1. Warum sind Holzfensterdichtungen wichtig?

2. Wie bestimme ich die richtige Fensterdichtung? Wie ist eine Holzfensterdichtung aufgebaut?

3. Welche Arten von Holzfensterdichtungen gibt es?

1. Flügelfalzdichtung

2. Überschlagdichtung

3. Verglasungsdichtungen

4. Gibt es verschiedene Formen von Holzfensterdichtungen?

1. Lippendichtungen

2. Hohlkammerdichtungen

5. Aus welchem Material bestehen die Fensterdichtungen?

1. TPE

2. Silikon

6. Was tun wenn keine Nut in meinem Holzfenster vorhanden ist?

7. Wann sollte man Holzfensterdichtungen austauschen?

8. Gibt es spezielle Pflegehinweise für Dichtungen von Holzfenstern?

1. Warum sind Holzfensterdichtungen wichtig?

Fensterdichtungen für Holzfenster sind spezielle Dichtungsprofile, die entlang der Ränder von Holzfenstern angebracht werden, um eine luft- und wasserdichte Abdichtung zu gewährleisten.

Holzfensterdichtungen passen sich der Optik der Holzfenster an und haben eine natürliche Dämmwirkung. Die Gummiprofile beeinflussen die Leistungseigenschaften eines Fensters, wie zum Beispiel die Schlagregendichtheit, die Luftdurchlässigkeit, den Schall- und Wärmeschutz sowie die Bedienung eines Fensters. Dieses ist im Hinblick auf steigende Anforderungen neuer Wärmeschutzverordnungen nicht zu verkennen. Zudem tragen sie maßgeblich zur Energieeffizienz bei, da sie den Wärmeverlust minimieren und somit Heizkosten einsparen. Holzfensterdichtungen sind also nicht nur ein praktisches, sondern auch ein umweltbewusstes Element in jedem Gebäude.

Regelmäßige Überprüfung und Wartung Ihrer Dichtungen in Fenster und Türen sind entscheidend, um die Wirksamkeit zu gewährleisten. Der Austausch undichter Gummiprofile sollte umgehend erfolgen, nach 15 bis 20 Jahren lässt die Wirksamkeit erfahrungsgemäß nach. Durch die richtige Pflege kann die Lebenszeit der Dichtung erheblich verlängert werden. Es ist also ratsam, die Dichtungen regelmäßig zu überprüfen, um die volle Funktionalität der Fenster langfristig zu erhalten.

2. Wie bestimme ich die richtige Fensterdichtung? Wie ist eine Holzfensterdichtung aufgebaut?

Eine Holzfensterdichtung ist wie folgt aufgebaut:

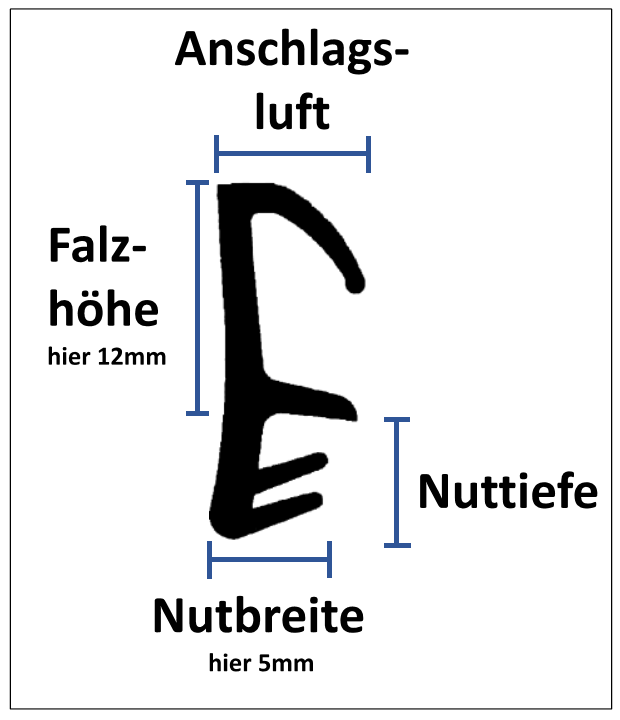

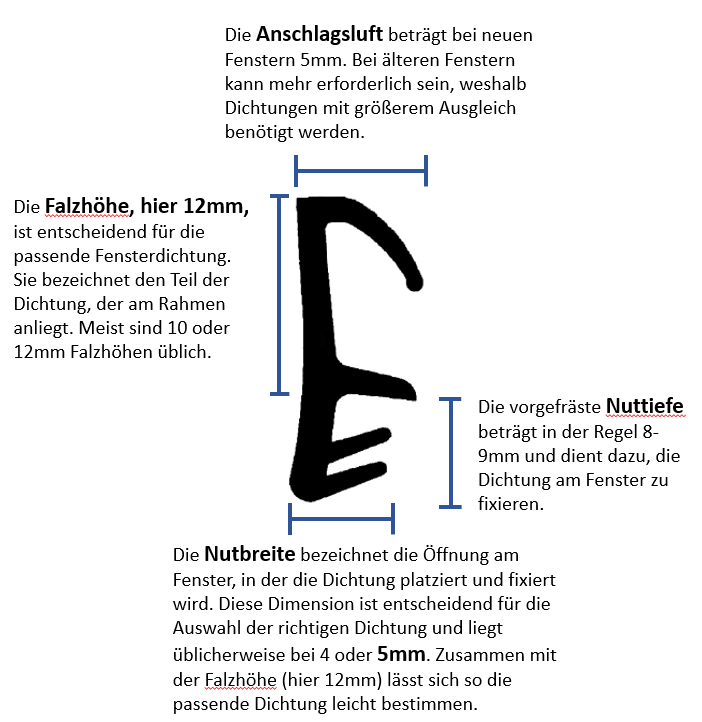

- Die Anschlagluft bezeichnet die Kopfbreite bzw. das Rückstellvermögen Ihrer Fensterdichtung. Diese beträgt bei neuen Fenstern 5mm. Bei älteren Fenstern kann mehr erforderlich sein, weshalb Dichtungen mit größerem Ausgleich benötigt werden. Die Anschlagluft bei Holzfenstern beträgt Werksseitig in der Regel 5mm, so dass die neue Holzfensterdichtung eine Kopfbreite bzw. Rückstellvermögen von von ca. 7,5 - 8,5 mm haben sollte.

- Die Falzhöhe ist das Maß der Dichtungsauflage am Rahmen mit 10, 12, 15 oder 18 mm. Dieses ist sehr entscheidend für die passende Fensterdichtung. Meist sind 10 oder 12 mm Falzhöhen üblich.

- In die (vorgefräste) Nuttiefe wird die Holzfensterdichtung eingeführt. Sie beträgt in der Regel 8 - 9 mm und dient dazu, die Dichtung am Fenster zu fixieren.

- Die Nutbreite bezeichnet die Öffnung am Fenster, in der die Dichtung platziert und fixiert wird. Diese Dimension ist entscheidend für die richtige Auswahl der Dichtung und liegt üblicherweise bei 4 oder 5 mm. Zusammen mit der Falzhöhe lässt sich hier die passende Dichtung leicht bestimmen.

Das Auswechseln von Holzfensterdichtungen stellt kein Problem dar und kann von jedem Hobby-Handwerker bewältigt werden. Generell sind eine Vielzahl von verschiedener Dichtungen für Fenster und Türen bei uns erhältlich. Die Chance passende Dichtungen, auch für ältere Fenster zu finden, ist relativ hoch.

3. Welche Arten von Holzfensterdichtungen gibt es?

Es gibt verschiedene Arten von Holzfensterdichtungen. Diese Dichtungen werden verwendet, um Fenster abzudichten und so den Energieverlust zu minimieren und den Schutz vor Feuchtigkeit zu gewährleisten.

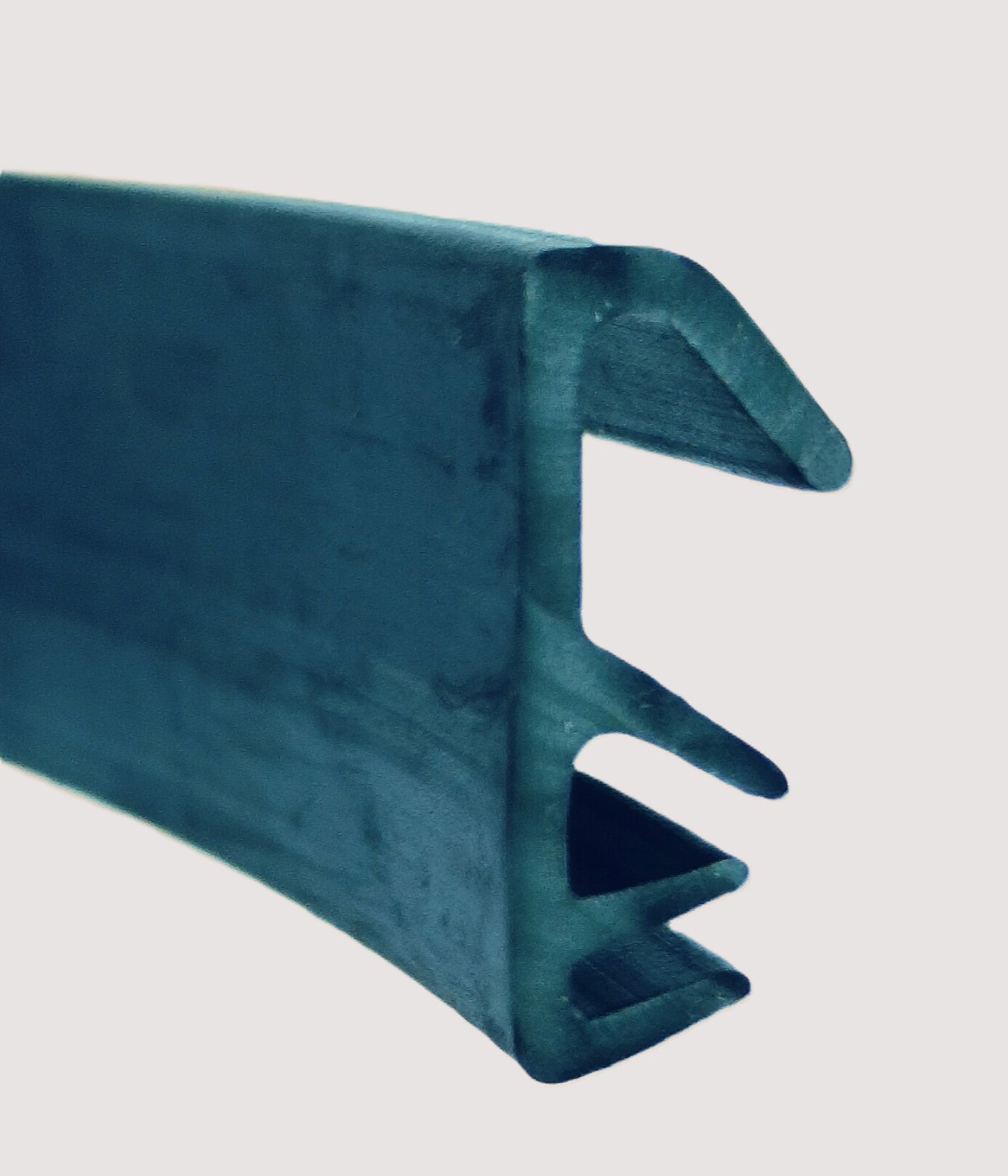

Flügelfalzdichtungen

Flügelfalzdichtungen werden für Holzfenster und Holztüren verwendet. Die Dichtung wird im Falz des Fensterflügels angebracht wird, um eine effektive Abdichtung zwischen dem Fensterflügel und dem Rahmen zu gewährleisten. Die Falz ist der Teil des Fensterflügels, der sich in den Rahmen einfügt, wenn das Fenster geschlossen ist.

Merkmale:

- Die Flügelfalzdichtung wird im Fensterflügel verbaut.

- Durch die stabile Bauform ist die Flügelfalzdichtung sehr effizient in Ihrer Funktion.

- Für die passende Flügelfalzdichtung spielen Nutbreite, Falzbreite und Kopfhöhe der Dichtung eine entscheidende Rolle.

Vorteile:

- Eine zuverlässige Abdichtung gegen unangenehme Witterungsbedingungen: Zugluft, Feuchtigkeit, Lärm und Pollenflug werden ferngehalten.

- einfache Montage und Wartung

- kostengünstig

Überschlagsdichtungen

Überschlagsdichtungen werden an der äußersten Ebene des Fensterflügels angebracht, die über den Rahmen hinausragt. Der Überschlag des Flügels wird so dicht an den Rahmen gedrückt. Es ist eine zusätzliche Dichtung, die nicht zwingend notwendig ist.

Vorteile:

- zusätzlicher Schutz gegen Zugluft und Feuchtigkeit

- einfache Montage

Verglasungsdichtungen sind ein spezielle Dichtungselemente, die in Fenstern und Türen verwendet wird, um die Verbindung zwischen dem Glas und dem Rahmen abzudichten. Dadurch wird eine effektive Isolierung erreicht und die Energieeffizienz des Gebäudes verbessert.

Merkmale:

- Die Wahl der passenden Verglasungsdichtung ist abhängig von Faktoren wie der Glasstärke, dem Rahmenmaterial und den individuellen Anforderungen an Dichtigkeit.

- Um herauszufinden um welche Dichtung es sich handelt und den Querschnitt der Dichtung zu ermitteln, muss die Scheibe ausgebaut werden.

- Fachgerechte Installierung ist hier besonders wichtig und sollte bei keinerlei Vorerfahrung an Fachpersonal abgegeben werden.

4. Gibt es verschiedene Profile von Holzfensterdichtungen?

Es werden hauptsächlich zwei Formen von Holzfensterdichtungen unterschieden:

| Lippendichtungen bestehen aus einer oder mehreren flexiblen Lippen, die beim Schließen des Fensters oder der Tür gegen den Rahmen gedrückt werden. Die Dichtungen bieten eine effektive Abdichtung gegen Zugluft und Feuchtigkeit. Sie passen sich gut den Konturen des Fensters an. |  |

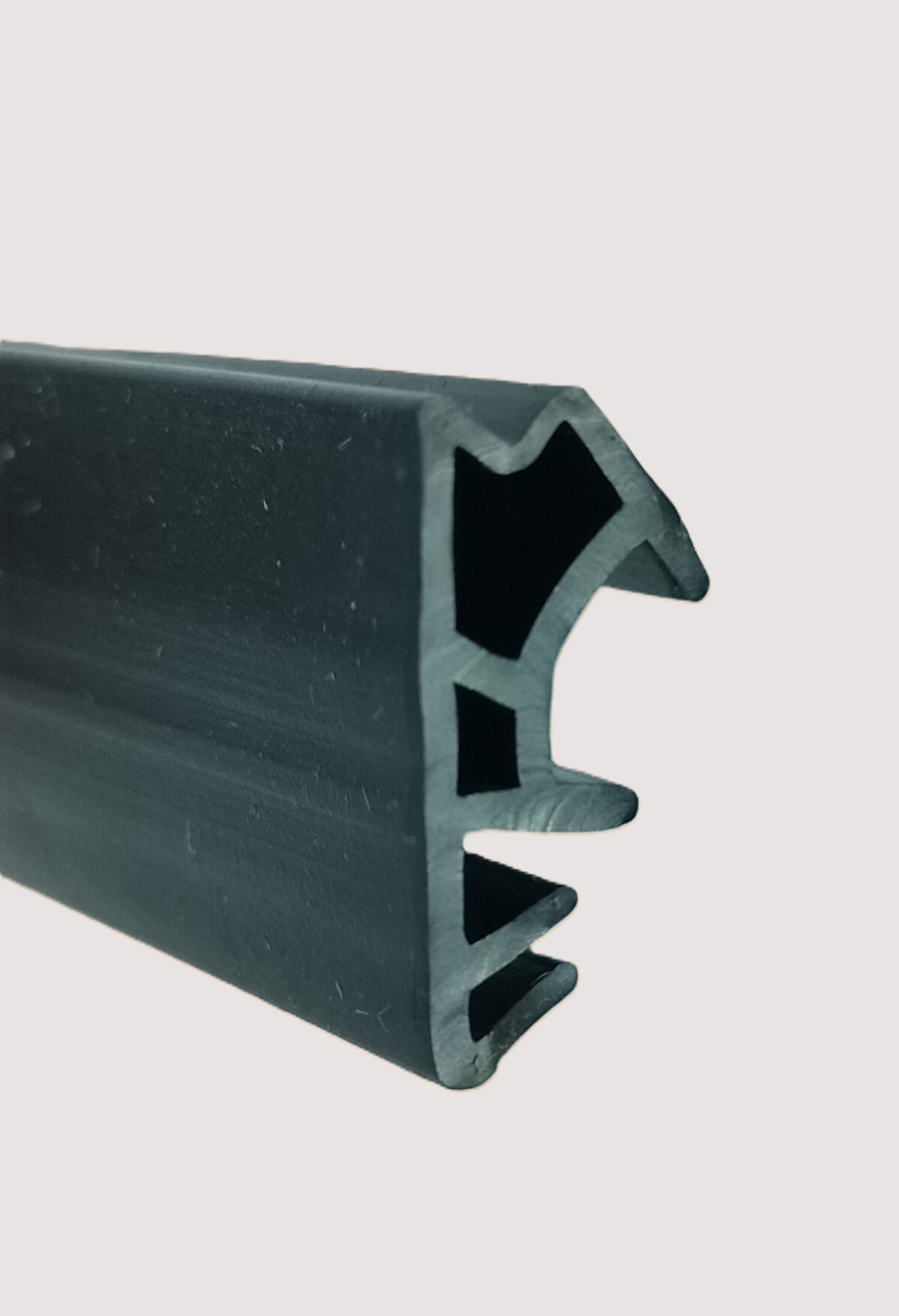

Hohlkammerdichtungen Beim Schließen des Fensters wird die Luft bei diesem Dichtungstyp komprimiert. Das hat zur Folge, dass der Fensterflügel sanfter schließt. Hohlkammerdichtungen verfügen über eine hohe Rückstellkraft, wodurch sie nach dem Öffnen wieder ihre ursprüngliche Form annehmen. |  |

Beide Dichtungsformen sind leicht zu montieren. Es ist wichtig die Dichtungen regelmäßig zu überprüfen und zu pflegen um eine effiziente Fensterabdichtung zu gewährleisten und Energie zu sparen.

5. Aus welchem Material bestehen die Fensterdichtungen?

Es gibt verschiedene Arten von Holzfensterdichtungen, die jeweils aus unterschiedlichen Werkstoffen hergestellt werden.

TPE Dichtungen vereinen die praktischen Eigenschaften von Gummi mit den Verarbeitungsvorteilen von Thermoplasten. Diese Gummidichtungen sind besonders flexibel und sorgen dafür, dass das Fenster dicht abschließt, um Zugluft und Feuchtigkeit fernzuhalten. Sie sind in verschiedenen Farben wie Schwarz, Braun und Weiß erhältlich. Durch ihre Flexibilität und Langlebigkeit tragen Gummidichtungen maßgeblich zur Wäremdämmung und Energieeffizienz von Holzfenstern bei.

Silikondichtungen bieten eine effektive Isolierung gegen Wind und Regen, was zu einer verbesserten Energieeffizienz des Fensters beiträgt. Wir verwenden eine spezielle Art von Silikondichtungen, die besonders langlebig, wartungsfrei und UV-beständig sind. Dadurch garantieren wir eine langfristige und zuverlässige Dichte, die den Anforderungen an jegliche Art von Holzfenster gerecht wird.

6. Was tun wenn keine Nut in meinem Holzfenster vorhanden ist?

Hier gibt es nun die Möglichkeit, eine Nut von 3 mm in den Fensterflügel nach zu fräsen und ein neues Dichtgummi zu montieren. Zum Nachrüsten neuer Fensterdichtungen bei dieser Art Fenstern, werden spezielle Profile aus Silikon verwendet. Dieser Vorgang ist sehr aufwendig und sollte nur von einem Fachbetrieb ausgeführt werden. Es handelt sich hier oft um Altbauten mit Kastenfenstern.

Fun Fact: Bis in die frühen 1960er Jahre wurden Holzfenster noch völlig ohne Nuten für Fensterdichtungen gefertigt wurden. Undichte Holzfenster konnten damals nur mit den aus der Werbung bekannten Klebedichtungen zusätzlich abgedichtet werden. Holzfenster ab den 1970er Jahren bis heute werden generell mit einer Nut zur Aufnahme einer Fensterdichtung hergestellt. Hier werden dann Flügelfalz- bzw. Stulp- oder Anschlagsdichtungen zum Abdichten neue Fenster verwendet.

7. Wann sollte man Holzfensterdichtungen austauschen?

Je nach Grad der Beanspruchung sollten Fensterdichtungen nach 15-20 Jahren ausgetauscht werden. Durch jahrelange temperaturbedingte und mechanische Einflüsse lässt die Funktion nach einer Zeit nach. Daher ist es ratsam, regelmäßig zu prüfen und gegebenenfalls die Dichtungen zu erneuern, um eine optimale Versiegelung und Energieeffizienz zu gewährleisten.

8. Gibt es spezielle Pflegehinweise für Dichtungen von Holzfenstern?

Ja, es gibt spezielle Pflegehinweise für Dichtungen an Holzfenstern. Um die Lebensdauer und Funktionalität von Dichtungen an Holzfenstern zu

erhalten, sind spezielle Pflegehinweise zu beachten. Dazu zählt die regelmäßige Reinigung von Rahmen, Dichtungen und Scharnieren sowie die

Verwendung von sanften Reinigungsmethoden wie Spülwasser. Besonders im Winter ist es wichtig, die Dichtungen trocken zu halten, um Feuchtigkeit und Schimmelbildung vorzubeugen. Kondenswasser sollte regelmäßig abgewischt werden, um die Dichtungen intakt zu halten. Eine regelmäßige Inspektion auf Beschädigungen oder Verschleiß ist ebenfalls ratsam. Durch die Beachtung dieser Pflegehinweise können Probleme wie Zugluft oder eindringende Feuchtigkeit vermieden und die Energieeffizienz der Fenster verbessert werden.